From Air to Liquid: Solidigm Powers the Future of AI Data Center Cooling

Solidigm Liquid-Cooled Data Center Solution Brief

Executive summary

Solidigm is a market leader in solid-state drive (SSD) technology and artificial intelligence (AI) infrastructure innovation. We are also an industry pioneer with the Solidigm™ D7-PS1010 SSD family, that includes some of the world’s first liquid-cooled SSDs for AI factory and enterprise data center environments.

As a proven SSD vendor of choice for AI infrastructure, Solidigm worked with NVIDIA to address eSSD liquid-cooling challenges, such as hot swapability and single-side cooling constraints. At GTC 2025, Solidigm demonstrated the first cold-plate cooled eSSDs featuring the Solidigm™ D7-PS1010 E1.S 9.5mm form factor for a fully liquid-cooled, rack-scale architecture with modern direct-to-chip (DTC) cold-plate cooling. For the NVIDIA NVL72 platforms with hybrid air-to-liquid cooling, Solidigm offers D7-PS1010 SSDs with traditional air cooling in the E1.S 15mm form factor.

Solidigm technology and products enable AI factories and enterprise data centers to achieve the highest densities and efficiencies with their current SSD platform, lowering total cost of ownership (TCO) and increasing return on investment (ROI).

Introduction

Data centers can range from shared rooms to dedicated buildings or even campuses. The largest data centers contain enterprise infrastructure to support diverse workloads at hyperscale.

Workloads differ across data centers ranging from traditional databases to modern hybrid cloud to emerging generative AI and agentic AI. Still, the increasing demand for AI has led to the development of purpose-built data centers, known as AI factories, that meet the extreme environmental requirements (e.g., power, temperature) of AI infrastructure.

The data center industry is experiencing a transition, presenting data center architects and designers with a dilemma — accommodating the remarkably different data center requirements of AI vs. enterprise racks.

Fan-based air cooling shifts to liquid cooling

Shifting to direct-to-chip (DTC) liquid cooling can future-proof data centers, allowing them to scale and meet both present and future requirements for enterprise-only, hybrid enterprise/AI, and AI-only rack designs.

While fan-based air cooling remains the traditional choice for data centers, a key challenge with air cooling is that it typically supports rack densities under 20 kilowatts (kW). It is supported by essential data center equipment, including rack-installed compute, storage, and network systems, which works for more traditional low-power enterprise rack designs. Unfortunately, it struggles in the face of today’s high-power AI racks.

DTC liquid cooling enables significant improvements in data center power usage effectiveness (PUE). A PUE of 1.0 represents perfect energy efficiency, where all power is dedicated to IT equipment with no overhead for cooling or other operations. Achieving a PUE of 1.1, considered near optimal, requires advanced cooling technologies to minimize energy usage. Liquid cooling is essential for consistently reaching this efficiency, as it addresses the scalability and density demands of modern data centers while significantly lowering cooling power consumption. DTC also allows data centers to support infrastructure and rack densities that would be unattainable with traditional cooling methods.

Data center rack cooling options

Enterprise rack designs with typical densities of under 20 kW each can continue with air cooling for the foreseeable future. However, some AI rack designs now require liquid cooling to manage densities over 100 kW, and road maps reveal that single-rack densities over 500 kW that require only direct liquid cooling are expected well before the end of this decade.

1. Air cooling only

Traditional air cooling moves air from the cold aisle to the hot aisle, absorbing heat from IT equipment along the way to support typical enterprise rack densities up to 20 kW. Internal fans drive most air movement of rack-mounted equipment (e.g., servers, GPUs, CPUs) but it is sometimes augmented with extra fans, at additional cost, to enhance air flow.

2. Hybrid air-to-liquid cooling

An advanced form of air-cooling is hybrid air-to-liquid cooling. This system adds a rear door heat exchanger (RDHx) for single racks. For multiple racks it can add a rack cooling system (RCS) to support higher rack densities. Both of these solutions increase costs and rack space consumption. Purchasing RDHx and RCS systems increases capital expenses, and running them continuously will increase operational expenses. Hybrid cooling is not fanless liquid-only cooling or DTC.

3. Direct-to-chip liquid cooling

Modern direct-to-chip liquid cooling, also known as fanless liquid-only cooling, relies on recirculating a specialized coolant using plumbing to support AI rack densities beyond 100 kW. DTC coolants, typically a mix of water and additives, are highly effective, and DTC plumbing precisely circulates the coolant where needed. Achieving this level of thermal control delivers competitive advantages by improving data center efficiency and optimizing rack space utilization.

Two stages of closed loops remove heat from data center racks. Stage one removes heat from hot rack components (e.g., chips) and systems (e.g., servers) to coolant distribution units (CDUs), and stage two removes it from CDUs to data center facility heat exchangers (e.g., heat pumps).

Liquid cooled D7-PS1010 in E1.S 9.5mm form factor

Liquid cooled D7-PS1010 in E1.S 9.5mm form factor

Benefits of direct-to-chip liquid cooling

Improved energy efficiency: Liquid cooling enables lower PUE, helping to achieve values as low as PUE 1.1. It reduces the need for energy-intensive air-cooling systems (e.g., CRAC units and chillers) and can handle high thermal loads with less energy consumption.

Increase rack density: Eliminates the practice of underutilizing rack space to overcome rack power and cooling limitations. Higher density means fewer racks are needed for the same compute capacity, reducing the floor space required.

Gain competitive advantages: Liquid cooling allows AI data centers to support high rack densities of 50 kW to100 kW or more, enabling the deployment of the most powerful GPUs required for emerging AI and machine learning workloads.

Future-ready data centers: Creates flexible data centers with the ability to scale to support any combination of mixed requirements.

Solidigm SSD solutions for DTC

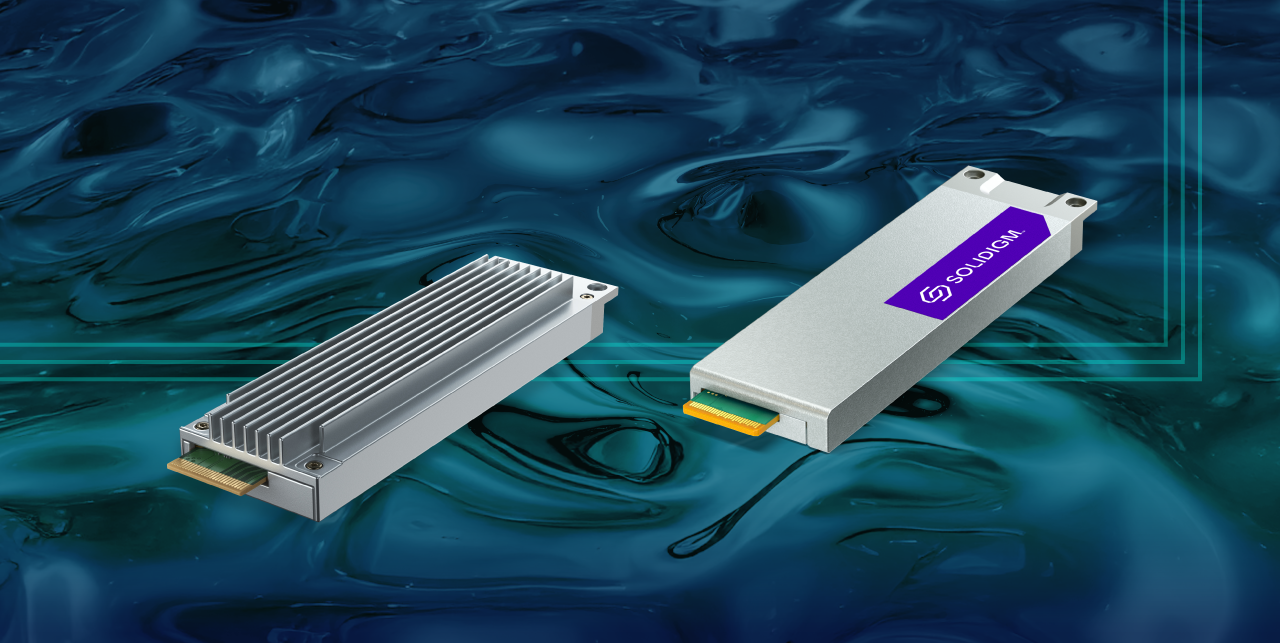

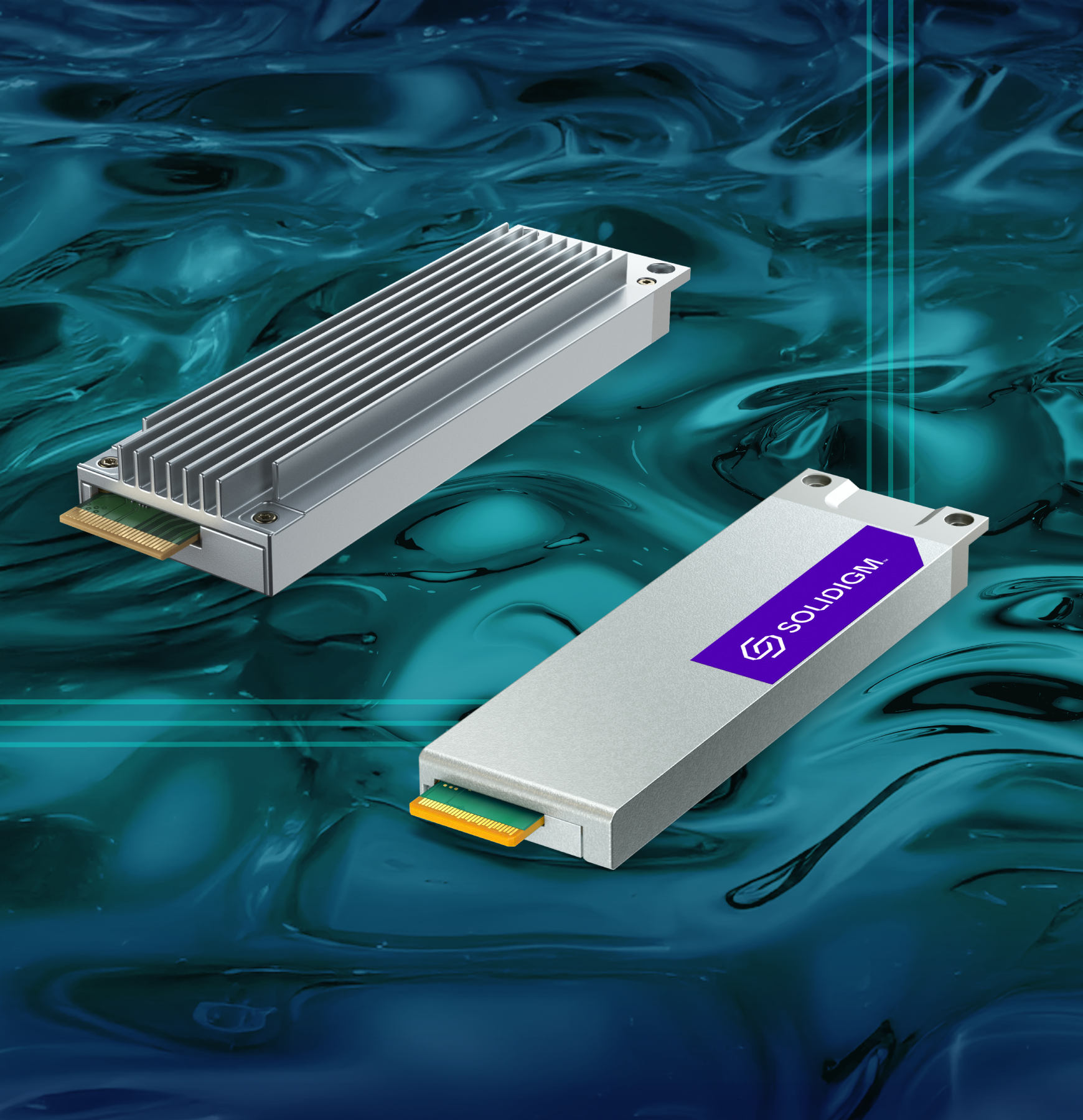

The Solidigm D7-PS1010 SSD product family offers class-leading performance for real-world AI and enterprise data center workloads. Designed for modern and next-generation servers, these SSDs deliver up to 97% IOPS consistency throughout the life of the drive to help maximize ROI. They are available in liquid or air-cooled 9.5mm and air-cooled 15mm models.

Data centers can standardize on D7-PS1010 SSDs regardless of their cooling infrastructure preferences because they are available in liquid-cooled and air-cooled versions. D7-PS1010 SSDs in the E1.S 9.5mm form factor are the first to be approved for the NVIDIA GB300 NVL72 fully-fanless system. Models in E1.S 15mm form factor are approved for the NVIDIA NVL72 systems with hybrid (air-to-liquid) cooling.

E1.S 9.5mm models support direct liquid cooling and require up to 84% less energy for cooling than competing E1.S 15mm models that support traditional air cooling. Also, the Solidigm air-cooled E1.S 15mm models require up to 34% less energy for cooling than competitor products.

| Model | D7-PS1010 |

| Form Factor | Liquid or air cooled E1.S 9.5mm, Air cooled E1.S 15mm, E3.S, or U2 |

| Capacity | 3.84TB or 7.68TB |

| Interface | PCIe 5.0 x4, NVMe |

Key features of the Solidigm D7-PS1010 SSD

Unified SSD platform: One SSD family with a variety of form factors and capacities for AI and enterprise data centers.

Advanced cooling options: Specialized models supporting modern liquid cooling and traditional air cooling.

Unified (single) cold plate: The industry’s first liquid-cooling-ready SSDs with a single plate cooling both sides of the SSD.

Unmatched performance efficiency: Up to 70% better IOPS/watt than competitor SSDs improve efficiency without sacrificing performance.

Consistent SSD performance: Up to 97% IOPS consistency across the life of the SSD using a PCI Express 5.0 x4 NVMe interface.

Built-in diagnostics and monitoring: Simplify error reporting, facilitate remote troubleshooting, and enable predictive maintenance.

Hot swap support: Improve data center serviceability by replacing SSDs while AI and enterprise servers remain online.

Conclusion

Solidigm is the trusted choice for SSD infrastructure and the storage foundation for tomorrow’s data centers for AI and enterprise workloads.

With the introduction of the D7-PS1010 SSD family, Solidigm is once again blazing the trail by achieving new industry milestones. This SSD family provides unmatched innovation, performance, efficiency, and reliability for data centers, whether their rack designs include liquid cooling, air cooling, or a hybrid mix of both.

Solidigm D7-PS1010 models in the E1.S form factor are the world’s first SSDs approved for the direct liquid-cooled NVIDIA GB300 NVL72 platform, proving our commitment, achievement, and leadership in storage solutions for AI and enterprise data centers.

About the Author

Dave Sierra is a Product Marketing Analyst at Solidigm, where he focuses on solving the infrastructure efficiency challenges that face today's data centers.